Slittering Line

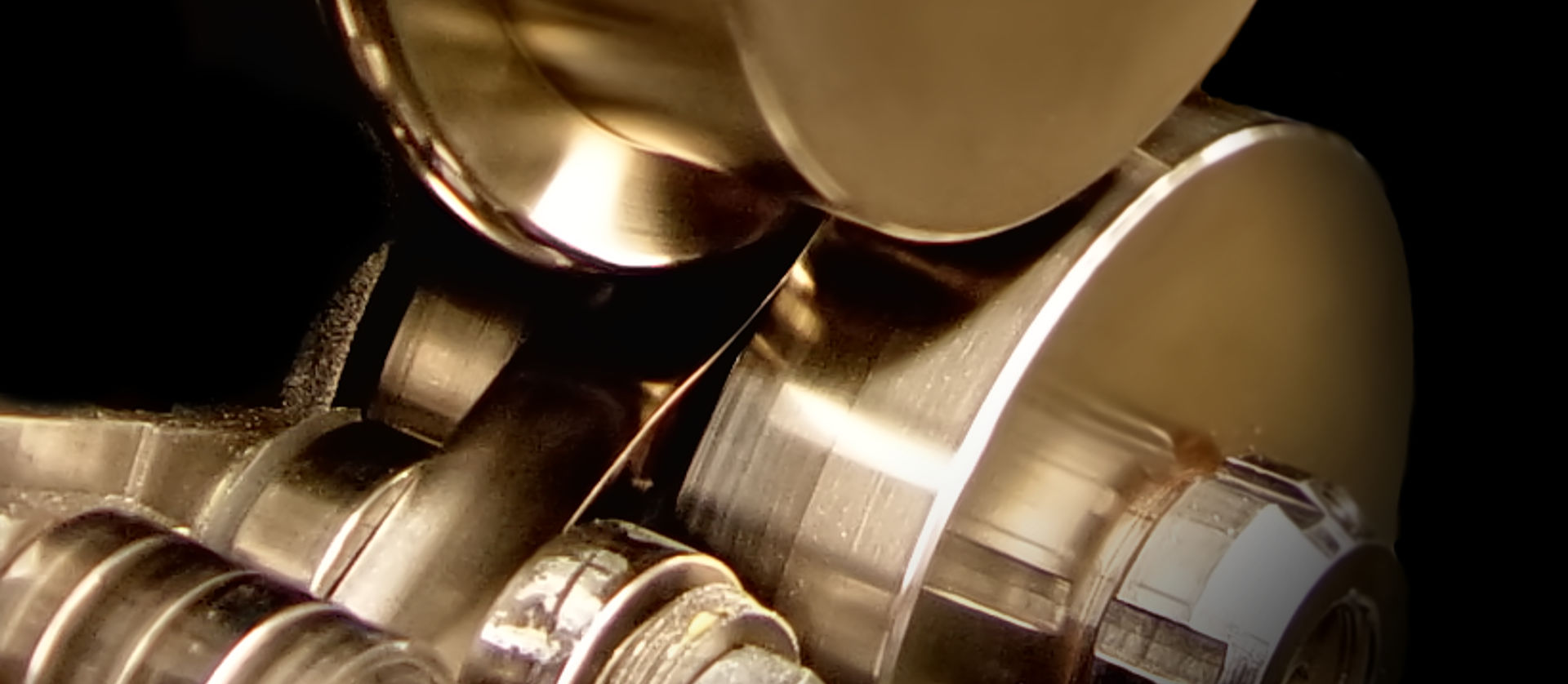

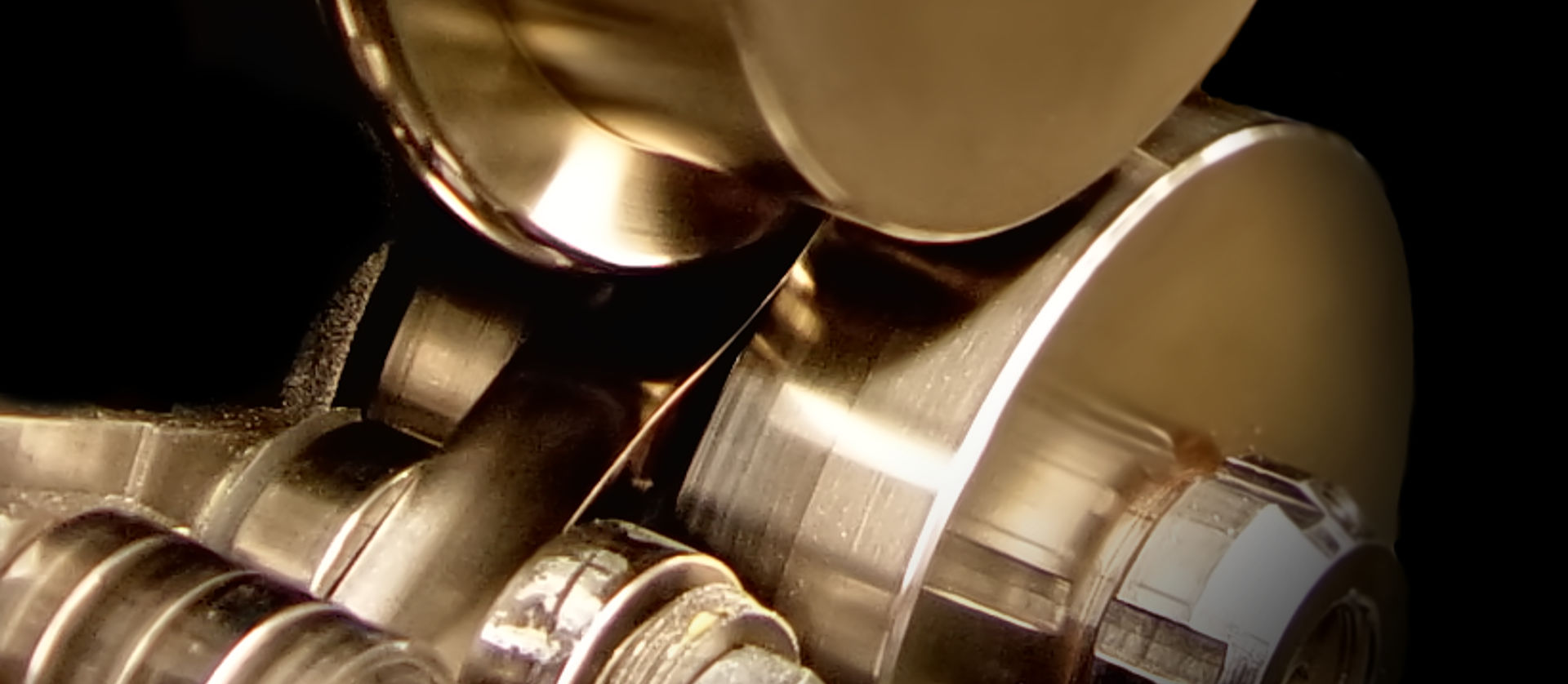

Circular shears with integrated deburring and winding unit

Since 2001 Cobra is proud to run one of the most innovative strip steel processing lines for narrow strips.

The line features 10 winding units, integrated deburring and two high performance welding units. By utilizing different welding processes we are enabled to “endlessly” link various materials to large coils. Strips up to 0.2 mm thickness are processed by laser welding, while thicker materials up to 0.8 mm are welded by a micro-plasma source.

In 2021 our strip steel processing has been upgraded to handle coil weights of up to 1000 kg per unit.

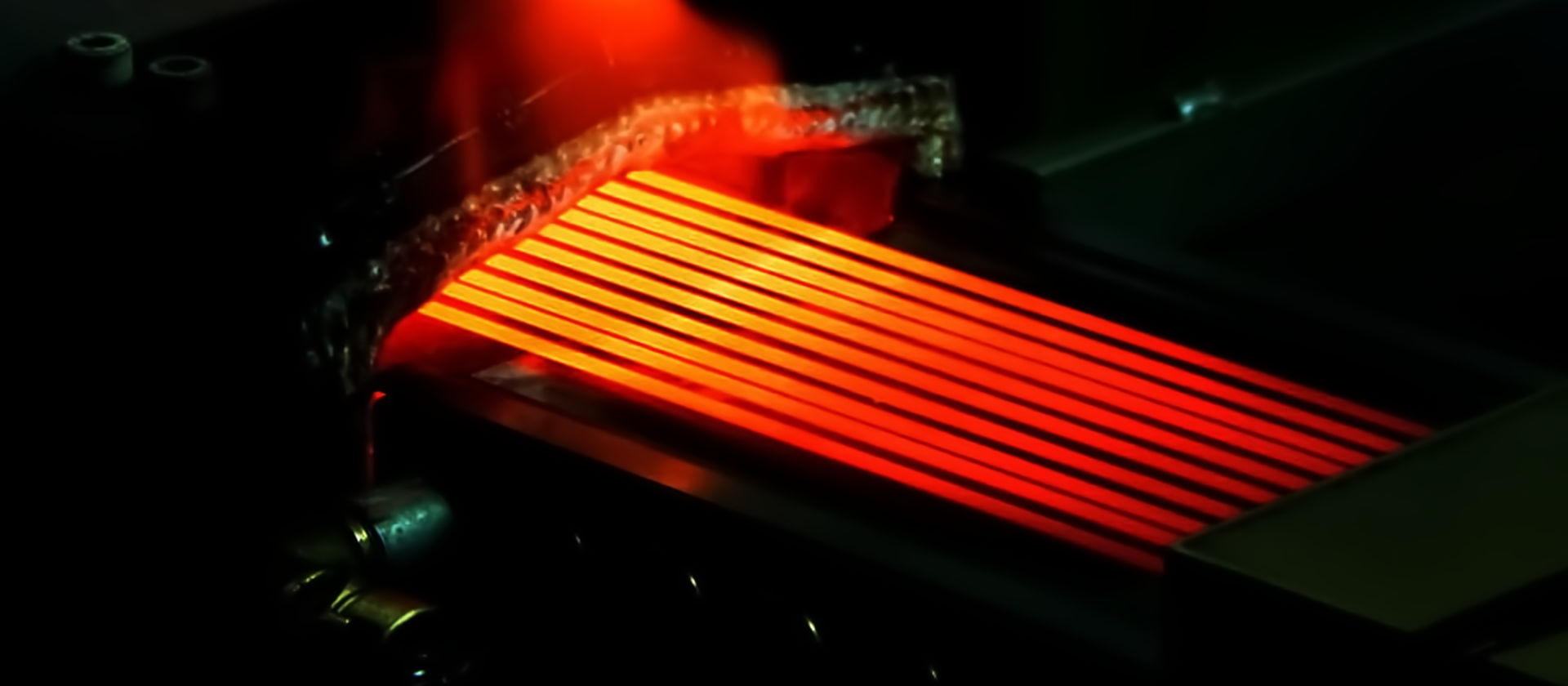

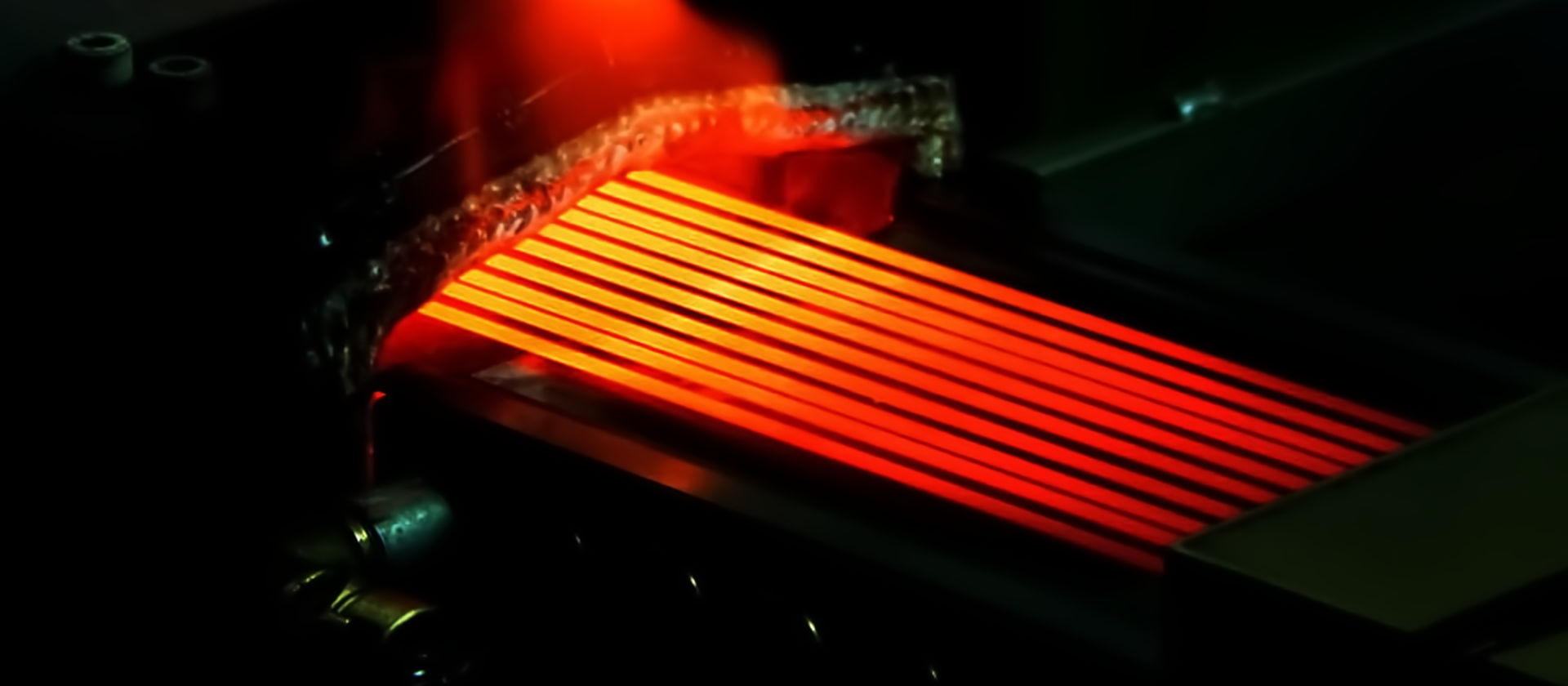

Heat Treatment

Hardening and heat treatment of measuring tape strips and spring strips is performed on our 8 heat treatment plants.

In addition to that we offer commission strip steel processing of flat wires and other strip steels under inert gas using hydrogen and nitrogen in compositions ranging from 0 to 100%. As a special feature we offer the so called thermal stretch levelling for stainless austenitic steels to minimize the saber of the strips by high temperature stretching (up to 600 °C).

Initial start-up furnace 1 + 2

Hardening plant

Our furnaces are designed for temperatures up tp 1200 °C. Using innovative isolation materials and energy efficient heating we achieve low energy consumption and best processing results.

The use of hydrogen ensures maximum heat transfer rates during the chilling process to produce non deforming strips and prevent internal tension.

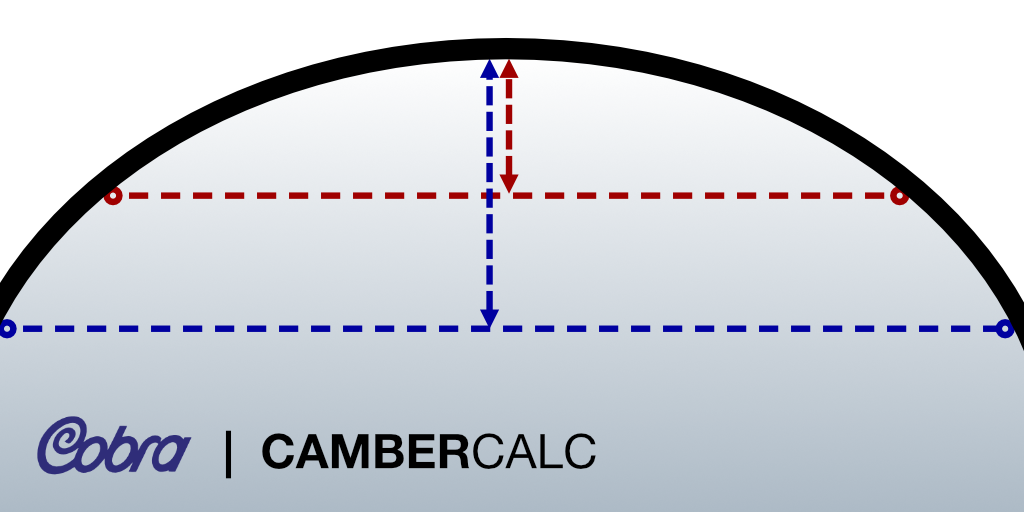

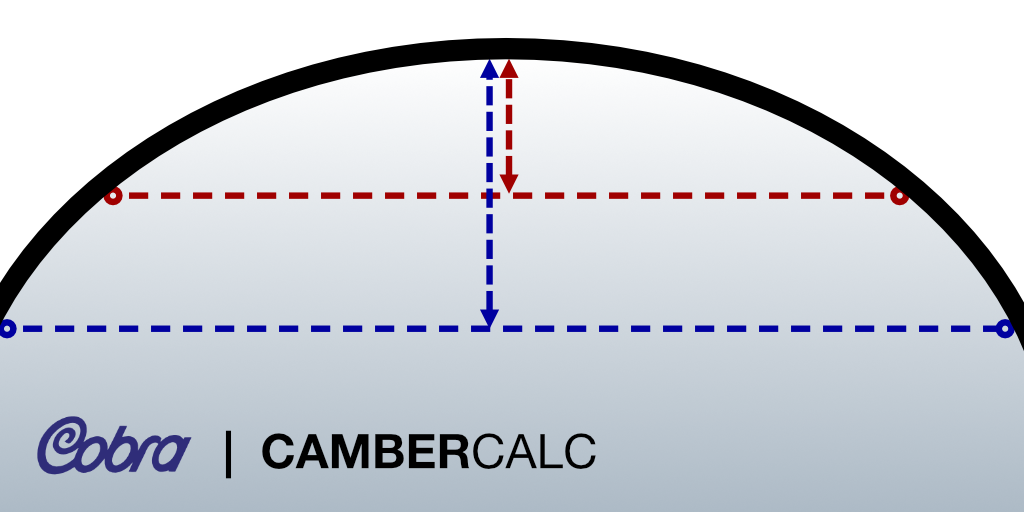

Camber Calculator

The conversion of straightness deviation is a non-linear equation. With our handy Camber Calculator you can convert the known deviation to any length.

Just input the saber y1 for a given length x1 and the calculator will do the rest for you to output the camber y2 for any desired length x2.

| Length x1 = | m |

| Camber y1 = | mm |

| Length x2 = | m |

| Camber y2 = | mm |

| Length x1 = | ft. |

| Camber y1 = | in. |

| Length x2 = | ft. |

| Camber y2 = | in. |

Edges and Surfaces

During the cutting process all strips are duburred by default to significantly decrease dangerous cutting injuries at our clients and own workers.

For many products a deburred edge is sufficient. For more advanced use cases we offer edge grinding on our new egde processing facility. For a minimum strip width of 2 mm and a minimum thickness of 0.08 mm we grind and polish the cut edge. As a result the risk of fatigue failure due to micro fractures is significantly reduced.

Furthermore our new strip steel processing facility enables us to polish the strip surface as well as to specifically grind to an RZ value of 25, the ideal basis for adhesive bonding.

For all applications

Edge and surface processing

Default deburring, egde grinding or surface polishing: With our innovative processing plant we deliver strips for the highest standards in the industry.

Laquering

Coating facility

For corrosive protection or as electrical isolation many of our products are coated specifically for your desired thickness of 15 µm and below.

Even special lacquers as a primer for polyamid coating can be used. The most commonly used colors are white and yellow for measuring tapes. If requested, blue, green, red or any custom color is possible as well.

Coating for electric isolation

Coil fuse

The development of isolating coatings for circuit breakers was a formidable challenge in lacquer technology. For our customer Hager we managed to achieve tolerances of 0,002 mm for coating thickness and 0,008 mm for material thickness.

Our target: 3.5 millon meters. Every year.

Cambering

Profiling facility for measuring tape strips

The special cambering of strip steel processing is done by our innovative cambering facility, which has been custom engineered for this purpose. The term “cambering” is a synonym for producing concave strip steel for extended stability of thin strips.

This unit was developed for the production of cold rolled strip steel and can produce various similar types of strip steel: cambered or profiled spring strip steel, roll-up tapes for click wrist-bands and slap-wraps, spring strip steel for antennas… .

Two-state strip steel

With one press on the red “button”, this 50 cm ruler rolls up immediately to fit in any pocket.

Spooling

Especially with flat wires and narrow measuring tape or spring steels, winded coils ensure a greatly reduced auxiliary process time when the steels are further processed to precision-blanked pieces or other types of products.

For a safe and efficient transport we offer high performance spooling on steel and one-way coils.

Our in-house developed traverse spoolers are designed to accurately wind strips from 2 x 0.1 mm to 30 x 0.5 mm with a maximum coil weight of 1000 kg.

Innovative processing:

Strip steel for advanced challenges

Article (german) our high performance winding unit (from Blechnet Edition 4/2016)