Our Products

stainless and martensitic strips 0.06 - 0.8 mm

Hardening

of strip steel and flatwire of 2 - 30 mm width

Cutting

of steel, aluminium, copper and brass strips

Production

cutting, deburring, hardening and lacquering

Production

Innovative machines for strip steel production. Developed by Cobra Engineering.

Slittering Line

Circular Shears

Hardening

H-Hardening Plant

Edges and Surfaces

Lacquering

Cambering

Spooling

Strip Steel Coil Calculator

Use our Cobra Coil Calculator to get you coil weight and length easily.

Enter strip width and thickness

Resulting length

Inner and outer diameter of single coil

Resulting weight of single coil

Enter strip width and thickness

Resulting length

Inner and outer diameter of single coil

Resulting weight of single coil

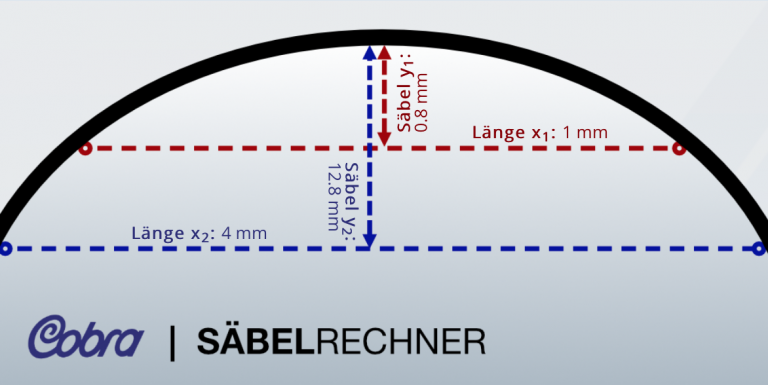

Also check out our handy Camber Calculator to get the non-linear deviation of straightness for any strip steel length.

Specifications

Our products for your application.

- Width: 2 – 30 mm

- Thickness: 0.06 – 0.8 mm

Width tolerance

- Standard tolerance: + 0.1 – 0.15 mm

- Extended tolerance: ± 0.02 mm

Thickness tolerance

- In accordance with EN 10140

- Optional extended tolerances T3, T4

Surface

- bright hardened

- yellow/blue tempered

- phosphate treated, lacquered

- bright polished

- brushed

Edges

- neat cut

- deburred

- rounded

Cold rolled and und hardened strip steel (stainless)

- Tensile strength 500 – 1000 N/mm2 unhardened carbon steel

- Tensile strength 1000 – 2100 N/mm2 for hardened spring steel and stainless tape measure strips

- Tensile strength 500 – 2100 N/mm2 für stainless strips

Flatness

- < 0.02 mm / 10 mm width

Straightness

- < 0.8 mm / 1000 mm

- Extended tolerance: 0.3 mm / 1000 mm

| No. | Designation | AISI |

|---|---|---|

| 1.1231 | C67S | 1070 |

| 1.1248 | C75S | 1075 |

| 1.1274 | C100S | 1095 |

| No. | Designation | AISI |

|---|---|---|

| 1.4021 | X20Cr13 | 420A |

| 1.4028 | X30Cr13 | 420B |

| 1.4034 | X46Cr13 | 420C |

| 1.4037 | X65Cr13 | 420F |

| No. | Designation | AISI |

|---|---|---|

| 1.4301 | X5CrNi18-10 | 304 |

| 1.4310 | X10CrNi18-8 | 301 |

| 1.4401 | X5CrNiMo17-12-2 | 316 |

| 1.4404 | X2CrNiMo17-13-2 | 316L |

| 1.4016 | X6Cr17 | 430 |

| 1.4571 | X6CrNiMoTi17-12-2 | 316Ti |

| 1.4541 | X6CrNiTi18-10 | 321 |

| 1.4372 | X12CrMnNiN17-7-5 | 201 |

| No. | Designation | |

|---|---|---|

| 1.0330 | DC01 |

| No. | Designation | |

|---|---|---|

| CW004A | Cu-ETP | |

| AW-5005 | AlMg1 |

Single coils

- Inner diameter: 230 – 400 mm

- Outer diameter: 600 – 800 mm

Coil winding

- Inner diameter: 300 mm, 400 mm or 500 mm

- Maximum weight: 1000 kg

Bars / pieces

- Length: 2 – 2000 mm

Quality control

For smallest tolerances and maximum precision.

Cobra System Engineering

News

New ideas for new applications.

We are ISO 9001 certified!

In December 2025, we reached an important milestone: our quality management system was successfully certified

Our contribution to saw blade manufacturing

As an experienced manufacturer of precision strip steel, we supply semi-finished products of the highest

Microcracks in Strip Products

What many people overlook: Even the smallest cracks at the edges of steel strip can

Videos

Maximum quality needs innovative processes.

Contact

Your way to the most innovative solutions for high performance strip steel.

Contact details

Cobra Bandstahl GmbH

Kinzigstr. 12

63607 Wächtersbach

phone +49 (0) 6053 30 16

telefax +49 (0) 6053 30 19

web cobra-bandstahl.de

mail info@cobra-bandstahl.de